state of the art – painting line at kitchen manufacturer

In the small North Jutland town of Jerslev, you find JKE Design which, for more than 50 years, has designed, manufactured and sold kitchens for Nordic homes. The company which is part of the BallingslövInternational AB group has the clear target that every time a JKE kitchen is designed, it should become ever greener.

In recent years, the demand for painted and espe-cially lacquered products has grown tremendously. As we have considerable focus on sustainability, we have closely followed the development of new water-based paints and varnishes, says Mads Radoor Sørensen, Production Manager.

The future is water-based paint

Our kitchens are coated in the strongest paint/var-nish in the market and we will not compromise on that. But modern water-based paints and varnishes are now so good and so durable that we can make the change and, thus, become more sustainable and create a healthier working environment.

The increase in demand has meant that, in the last two years, we have moved from one to three production shifts and the development seems to continue. In light of that fact, we decided to invest in the future and move from hand-painting our products to using a complete and fully automated painting line from Ceetec on Funen. At the same time, we chose to switch to a system of water-based lacquers which we have worked on for many months together with our good supplier Aalborg Farve & Lak, continues Mads Radoor Sørensen.

Together, we have followed the development of water-based UV products and inter alia conducted tests at the manufacturer Hesse Lignal in Germany to confirm that the products are at least as good as the ones we use now. Many have previously tried water-based products with mixed results but, now, they are really good, emphasises Mads Radoor Sørensen.

Bo Bech Jensen and Kim Nielsen who are both sales consultants at Aalborg Farve og Lak add that theysucceeded in identifying a system of lacquers that matches the system and the durability require-ments known by JKE today but which contains virtu-ally no solvents. For both clearcoats and pigmented paints, the contents of VOC are below 4 % which means a reduction of VOC of more than 90 % to the delight and benefit of all.

Complete painting line installed in just five days

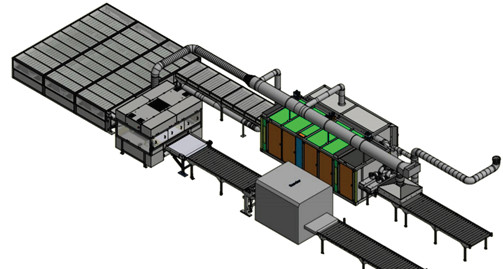

We chose to go all-in and invest in a complete paint-ing line which means that we have automated sand-ing, painting and drying as well as handling between the machines. We researched the market thoroughly from the outset and the choice fell on the Danish company Ceetec as we had good chemistry and felt they listened to our special wishes for the plant and layout. The Ceetec DNA means that a high level of customer service is second nature and that means a lot to us. They are only a few hours away and react immediately if situations arise where we need help.

An additional parameter for choosing Ceetec was their concept of modular solutions which involves a very short installation time as everything is preassembled and tested at the factory before shipment. We wanted to install the plant in December to take advantage of our shutdown between Christmas and New Year and were honestly a bit sceptical when Ceetec promised installation in just five days.

But it happened exactly as they had promised and that is impressive for such a large plant, says Mads Radoor Sørensen. With the new paint line, we have increased capacity so much that we have been able to revert from three to one shift while at the same time saving the whole, long drying process as the products are now dry and can be handled as soon as they leave the plant.

This investment gives us the opportunity to continue our growth journey and contributes to the target of ever greener kitchens, concludes Mads Radoor Sørensen.

Jesper Frandsen, owner of Ceetec, says that the line at JKE Design is one of the best plants delivered by the company to date and that the furniture and kitchen industry should look this way for inspiration for future interior painting.

Facts – new, water-based system of lacquer

The system of lacquer is from Hesse in Germany and contains virtually no solvents.For both clearcoats and pigmented paints, the VOC contents are below 4 %. JKE Design has attained a system of lacquers that meets the requirement of being able to tone trendcolours as well as all NCS colours. The system is almost identical to the conventional solvent-based systempreviously used but, with the environment in mind, there will be a reduction in VOC of over 90 %.

Bo Bech Jensen and Kim Nielsen – Sales Consultants, Industry, at Aalborg Farve & Lak

The line provided by Ceetec consists of:

- Inlet line

- Turbo blower, removing all dust prior to the objects passing the spray zone

- Ceetec DuoFlex sprayer with windows on all four sides and two circuits

- Side-slidable line with the option of adding heat

- 6-metre flash-off zone before objects moving into the furnace

- 6-metre furnace with six levels, thus achieving 36 metres of drying time

- UV tunnel

- Cooling zone

- Outlet line